Powder Coating Production and Composition

Powder coatings are formulated using the following raw materials:

- Binders (resins, hardeners, accelerators)

- Pigments and dyes

- Fillers

- Additives

The Process

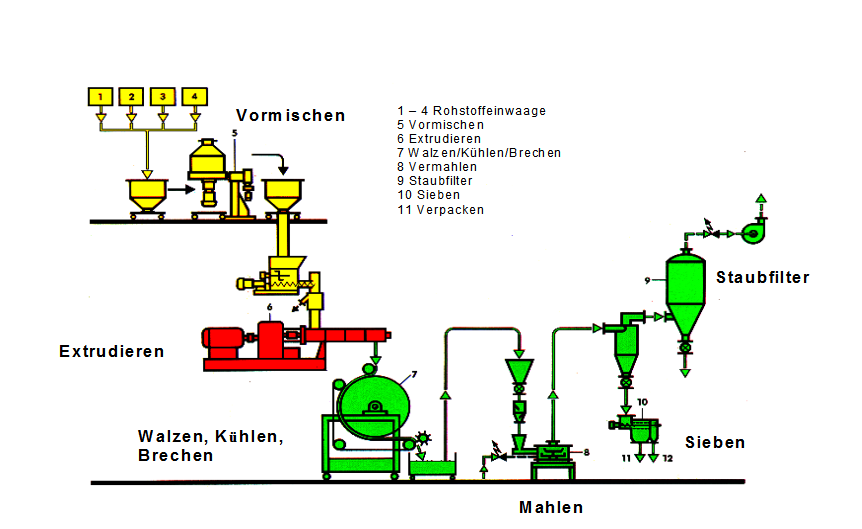

- The granulated and powdered raw materials are precisely weighed and homogenized in a mixer according to formulations developed by our laboratory. This dry blend is then melted and dispersed in an extruder at temperatures ranging from 90 to 130 °C.

- Upon exiting the extruder, the molten compound is rolled out using compression rollers and cooled on conveyor belts until it returns to room temperature. The resulting solid sheets are pre-crushed and processed into powder coating chips.

- These chips are then finely ground in a mill to achieve a defined particle size distribution.

- After classification, sieving, and thorough quality control, the finished powder coating is packaged in cartons, big bags, or containers—ready for delivery.

Optimized Production for Maximum Flexibility and Fast Delivery

Thanks to our specialized production lines, we ensure short lead times for all batch sizes—whether small or large. This high level of flexibility allows us to consistently meet the highest quality standards while guaranteeing fast and reliable delivery. Our entire manufacturing process is managed through an advanced production planning system (PPS), ensuring real-time transparency and coordination across all departments involved.

An Overview of Powder Coating Diversity

Powder coatings are solid, solvent-free coating materials that, once applied to a substrate, are melted and chemically cross-linked through heat. This process creates a seamless, highly adhesive surface finish. Thanks to efficient powder recovery systems, utilization rates of up to 98% can be achieved—making powder coating both cost-effective and environmentally friendly.

Powder coatings serve a wide range of functions, primarily focused on three key aspects:

| Decorative Aspect | Economical Aspect | Functional Aspect |

| · Colour

· Gloss · Flow · Texture |

· Low curing temperatures

· High Opacity · Efficient powder recovery · Environmentally friendly |

· Mechanical resistance

· Corrosion resistance · Weathering · Chemical resistance · Electrical insulation |